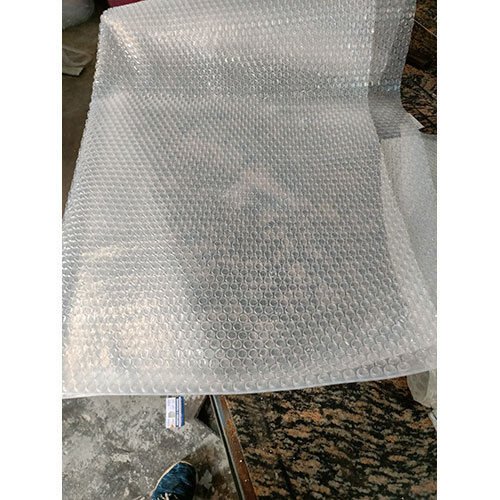

Air Bubble Packaging

Price 2 INR/ Piece

Air Bubble Packaging Specification

- Thickness

- 2 Centimeter (cm)

- Product Type

- Air Bubble Packging

- Material

- Plastic

- Bag Type

- Style

- Sealing & Handle

- Industrial Use

- packaging

- Size

- Standard

- Width

- 12 Centimeter (cm)

- Length

- 18 Centimeter (cm)

- Color

- Transparent

Air Bubble Packaging Trade Information

- Minimum Order Quantity

- 1000 Pieces

- FOB Port

- Delhi

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 100000 Pieces Per Week

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia

- Main Domestic Market

- Delhi, Haryana, Uttar Pradesh

About Air Bubble Packaging

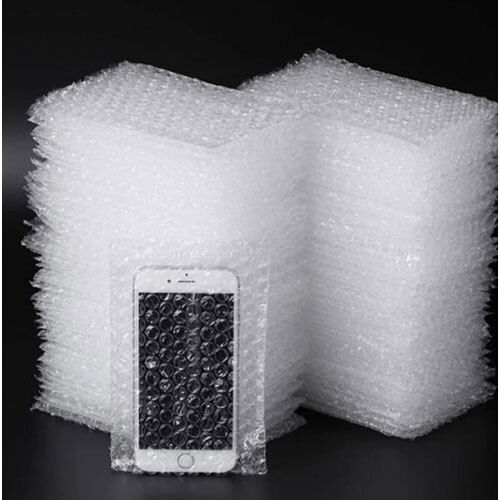

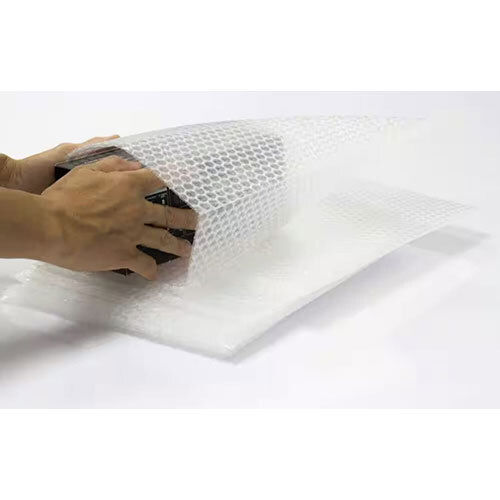

Air bubble packaging, most commonly known as "bubble wrap," is a transparent plastic material with a surface covered in evenly spaced, protruding, air-filled hemispheres or "bubbles." This unique design is what gives it its excellent cushioning properties.

Key Characteristics and Properties

-

Exceptional Shock Absorption: The air trapped within each bubble acts as a cushion, absorbing and dispersing impact forces. When an item is bumped, dropped, or subjected to vibrations during transit, the bubbles compress, preventing the force from reaching the product and causing damage.

-

Lightweight: Made from polyethylene film and filled with air, bubble wrap is extremely light, which helps reduce shipping costs and doesn't add significant weight to the package.

-

Flexibility and Adaptability: Air bubble packaging is highly flexible and can be easily wrapped around items of various shapes and sizes, from flat screens to irregularly shaped objects. It conforms to the product, providing a snug and secure fit.

-

Moisture and Water Resistance: The plastic film is non-porous and water-resistant, providing a barrier against moisture and dust. This is particularly important for protecting items sensitive to humidity or water damage.

-

Reusability: Bubble wrap can often be reused multiple times if it remains intact, making it a cost-effective and more sustainable option for packaging.

-

Transparency: Its transparent nature allows for easy identification of the wrapped item without the need to unwrap it, which is useful for inventory and storage.

-

Specialized Variants:

-

Anti-static bubble wrap: This type is designed to protect sensitive electronic components from static electricity, which can cause damage. It's often pink or blue to distinguish it from regular bubble wrap.

-

VCI (Volatile Corrosion Inhibitor) bubble wrap: This variant is treated with a chemical that prevents rust and corrosion on metal parts, making it ideal for packaging automotive components or machinery.

-

Bubble bags and pouches: These are pre-made bags or pouches of bubble wrap, often with a self-sealing adhesive strip, that provide a quick and easy packaging solution for small items.

-

Manufacturing Process

Air bubble packaging is typically made from a low-density polyethylene (LDPE) resin. The process involves:

-

Extrusion: The polyethylene resin is melted and extruded into two thin sheets of plastic film.

-

Forming the bubbles: One of the plastic sheets is fed over a drum with small holes. A vacuum is applied through the holes, suctioning the film into the shape of the bubbles.

-

Lamination and sealing: The second, flat sheet of plastic is then laminated over the bubble-formed sheet, trapping air inside the bubbles and sealing them in place with heat and pressure.

-

Finishing: The finished bubble wrap is then cut and perforated to create rolls, sheets, or bags.

Common Uses

Air bubble packaging is a go-to choice for protecting a wide variety of items across numerous industries, including:

-

Electronics: Laptops, smartphones, circuit boards, and other sensitive components.

-

Glass and Ceramics: Glassware, mirrors, pottery, and decorative items.

-

Moving and Storage: Wrapping furniture, art, and delicate household goods during a move.

-

E-commerce and Logistics: Providing protection for a wide range of goods shipped through online retail channels.

-

Automotive: Protecting delicate parts and components.

-

Medical Equipment: Safeguarding sensitive diagnostic and surgical instruments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Bags Category

Air Sheet Bags

Price 10 INR / Piece

Minimum Order Quantity : 1000 Pieces

Width : 12 Inch (in)

Style : Single String

Sealing & Handle : Heat Seal

Color : Transparent

EPE Bag

Price 2 INR / Piece

Minimum Order Quantity : 1000 Pieces

Width : 12 Centimeter (cm)

Style : Single String

Sealing & Handle : Other,

Color : Transparent

Air Bubble Bags

Price 2 INR / Piece

Minimum Order Quantity : 1000 Pieces

Width : 12 Centimeter (cm)

Style : Other,

Sealing & Handle : Other,

Color : transparent

GST : 07ABBFB9921H1ZG

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS