EPE Bag

Price 2 INR/ Piece

EPE Bag Specification

- Material

- Plastic

- Water Resistant

- YES

- Product Type

- EPE Bag

- Bag Type

- Style

- Single String

- Sealing & Handle

- Industrial Use

- Packaging

- Size

- Standard

- Width

- 12 Centimeter (cm)

- Length

- 18 Centimeter (cm)

- Color

- Transparent

EPE Bag Trade Information

- Minimum Order Quantity

- 1000 Pieces

- FOB Port

- Delhi

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 100000 Pieces Per Week

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia

- Main Domestic Market

- Haryana, Delhi, Uttar Pradesh

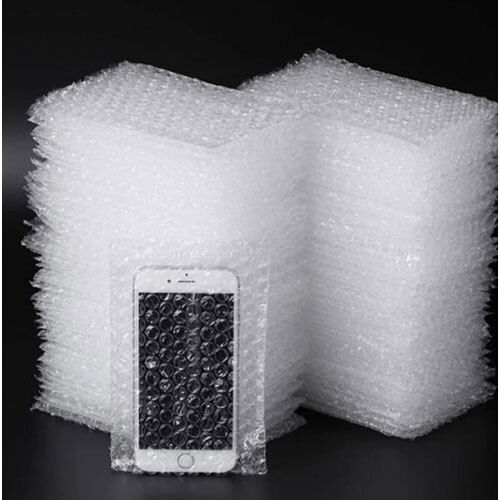

About EPE Bag

An EPE bag, also known as an EPE foam bag or EPE packaging bag, is a type of protective packaging made from Expanded Polyethylene (EPE) foam. This material is a lightweight, closed-cell foam made from low-density polyethylene resin.

Key Characteristics and Properties

-

Excellent Cushioning and Shock Absorption: The closed-cell structure of EPE foam is filled with a large number of tiny, independent bubbles. This allows it to effectively absorb and disperse external impact forces, providing superior cushioning and protecting fragile or delicate items from damage during storage, handling, and transportation.

-

Lightweight: EPE is extremely light, which is crucial for packaging and shipping applications as it helps reduce overall weight and transportation costs.

-

Moisture and Water Resistant: The closed-cell structure prevents EPE from absorbing water, making it suitable for protecting products in humid or wet environments.

-

Flexible and High Plasticity: EPE foam is easy to process, cut, and mold into various shapes and sizes. It can be customized to fit specific products, ensuring a snug and secure fit.

-

Thermal Insulation: The trapped air within the closed-cell structure provides good thermal insulation, making EPE bags suitable for packaging temperature-sensitive items.

-

Chemical Resistance: EPE is resistant to many chemicals, oils, and solvents, which adds to its durability and versatility.

-

Non-Toxic and Odorless: EPE foam is a non-toxic material that doesn't produce harmful substances, making it safe for use with a wide range of products, including food and consumer goods.

-

Anti-Static: Some EPE bags are treated with an anti-static agent to prevent the buildup of static electricity, which is particularly important for packaging sensitive electronic devices.

-

Recyclable: EPE is a thermoplastic material that can be melted and reshaped multiple times, making it recyclable. This allows for it to be repurposed into new products, reducing waste. However, specialized equipment is often required for recycling, which can limit its recycling rate in some areas.

Manufacturing Process

EPE foam is produced by expanding polyethylene resin with a blowing agent under high heat and pressure. The resulting foam is then processed into sheets, rolls, or custom-molded shapes. To create EPE bags, rolls of EPE foam sheets are fed into a bag-making machine that automatically cuts and seals the material to create bags of various sizes and specifications.

Common Uses

EPE bags are widely used across various industries for protective packaging, including:

-

Electronics: Mobile phones, computers, monitors, components, and other sensitive equipment.

-

Glass and Ceramics: Glassware, porcelain, mirrors, and other fragile decorative items.

-

Appliances and Furniture: Providing cushioning and edge protection for large appliances and furniture during transit.

-

Crafts and Artwork: Safeguarding delicate and valuable crafts, statues, and other art pieces.

-

Logistics and E-commerce: Used as a common packaging material to protect goods during shipping and reduce transport costs.

-

Automotive: Protecting delicate components and parts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Bags Category

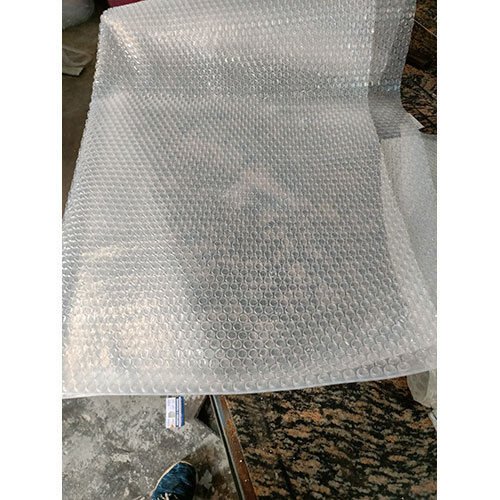

Air Sheet Bags

Price 10 INR / Piece

Minimum Order Quantity : 1000 Pieces

Product Type : Air Sheet Bags

Width : 12 Inch (in)

Style : Single String

Industrial Use : Other, packaging

Air Bubble Packaging

Price 2 INR / Piece

Minimum Order Quantity : 1000 Pieces

Product Type : Air Bubble Packging

Width : 12 Centimeter (cm)

Style : Other,

Industrial Use : Other, packaging

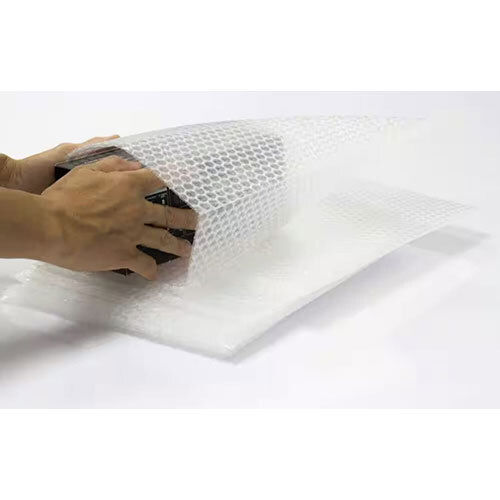

Air Bubble Bags

Price 2 INR / Piece

Minimum Order Quantity : 1000 Pieces

Product Type : Air Bubble Bags

Width : 12 Centimeter (cm)

Style : Other,

Industrial Use : Other, packaging

GST : 07ABBFB9921H1ZG

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS